Technology Marketplace

Fig. 1—Wenner Engineering’s Hydra-Cell D10 Series sealless high-pressure pump.

Seamless High-Pressure Pumps

Winner Engineering’s Hydra-Cell D10 Series seamless pumps (Fig. 1) operate at discharge pressures up to 1,500 psi. Used for a wide range of processing applications, the pumps have a flow capacity of 4¼ gal/min with a motor speed of 790 rev/min when performing at the maximum pressure rating. The pumps’ seamless design and spring-loaded, horizontal, disk check valves allow them to handle viscous fluids and abrasive particulates up to 500 microns in size.

For more information, visit www.wannereng.com.

Fig. 2—Shimadzu’s GCMS-QP2020 gas chromatograph and mass spectrometer.

Gas Chromatograph and Mass Spectrometer

Shimadzu’s single quadrupole GCMS-QP2020 gas chromatograph and mass spectrometer (Fig. 2) uses patented Advanced Scanning Speed Protocol technology, allowing scans of samples at high speeds without sensitivity loss or spectral distortion. The quadrupole mass filter is able to obtain accurate mass assignments and is equipped with a pre filter to reduce the influence of contamination on the main filter. It has a high-sensitivity ion source and ion optics to enhance ionization and transport efficiency, and its ecology mode reduces the costs associated with power and carrier gas consumption.

For more information, visit www.ssi.shimadzu.com.

Fig. 3—CS Unitec’s Model 5 8002 7000 pipe cutter.

Pneumatic Pipe Cutter

The Model 5 8002 7000 pipe cutter from CS Unitec (Fig. 3) cuts and bevels pipes of diameters ranging from 12 in. to 63 in. and wall thicknesses ranging from 0.25 in to 2 in. It is a two-speed pneumatic machine that operates at 1,800 rev/min for cutting and 350 rev/min for low-speed/high-torque beveling. The machine cuts ductile iron, nonferrous metal, polyvinyl chloride, plastic, and cement pipes. It bevels 40°, 60°, and 90° angles with optional blades for on-site weld preparation. The machine operates on an air volume of 77 ft3/min at 90 psi air pressure. It is ATEX-certified under Class II 2 GcT6 and can be used in industrial zones where flammable gas, vapor, mist, and dust may be present and where surface temperatures do not exceed 185°F.

For more information, visit www.csunitec.com.

Fig. 4—AMETEK’s Elite Series Wet-Mate high-pressure/high-temperature connector.

Subsea HP/HT Connector

AMETEK’s Elite Series Wet-Mate high-pressure/high-temperature connector is designed to operate in subsea oil and gas environments. The connector (Fig. 4) is 15.8 mm in diameter and has been functionally tested to 1,034 bar and temperatures as high as 150°C. It features a patented design in which concentric contacts are individually sealed within pressure-balanced, oil-filled plug and receptacle connector housings. That configuration protects both the plug and socket contacts from the external seawater environment and ensures repeated subsea mating capability at extreme pressures and temperatures.

For more information, visit www.ametek.com.

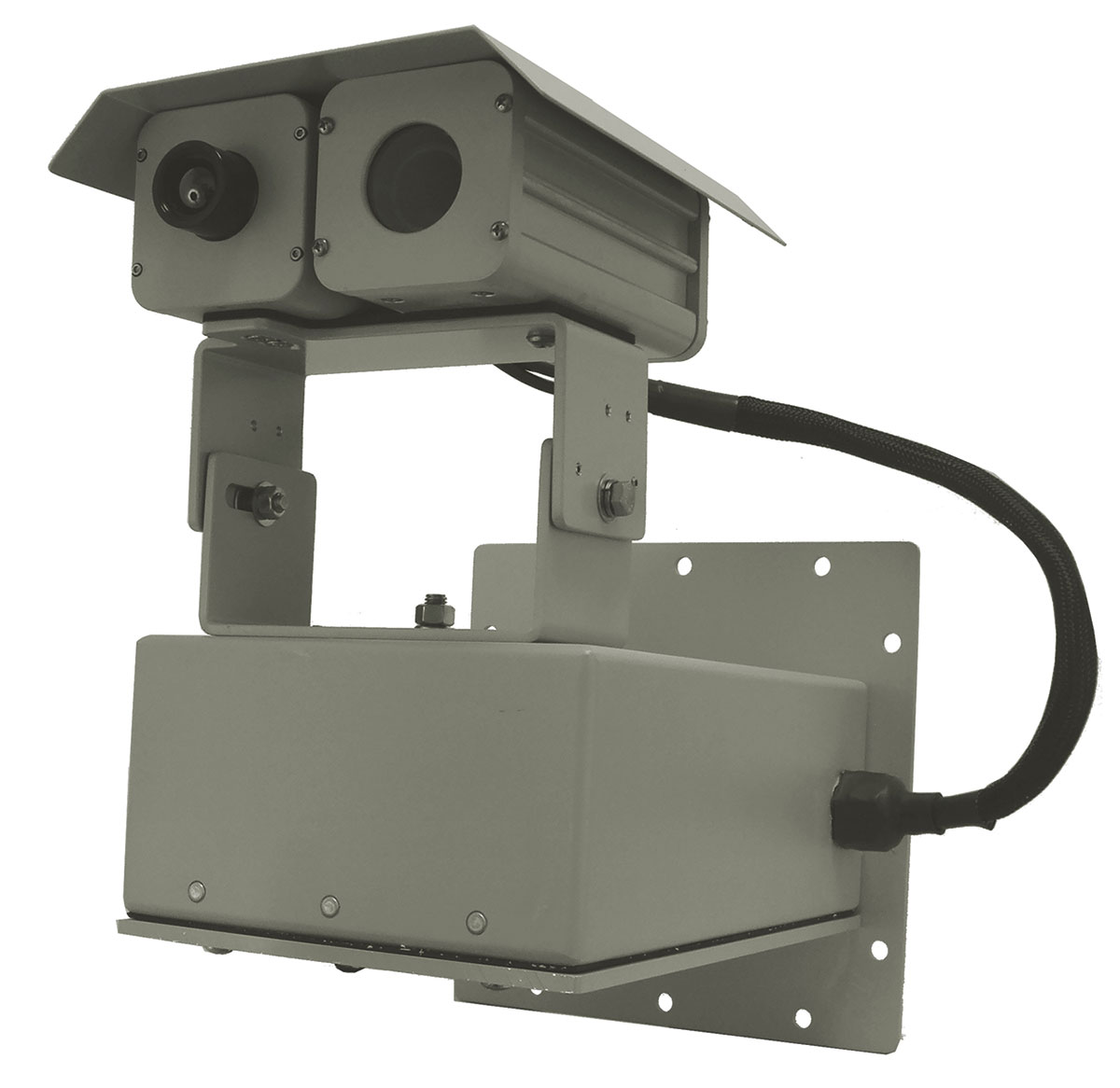

Fig. 5—Industrial Video and Control’s FV-3532-4 hydrocarbon leak detection camera.

Hydrocarbon Leak Detection Camera

Industrial Video and Control’s FV-3532-4 hydrocarbon leak detection camera (Fig. 5) incorporates proprietary algorithms to detect leakages of a variety of hydrocarbons in pipelines and tanks. The camera comprises a fixed-view optical imager and a thermal imaging sensor, which detect leaks of hydrocarbon fluids and high-pressure gases. When a leak is detected within a user-defined zone, a contact closure is activated to generate an immediate alarm. With camera management software, these alarms can be managed and communicated to a supervisory control and data acquisition system or a distributed control system using industrial protocols such as OPC or Modbus. The camera is housed in a weatherproof enclosure, making it suitable for use in a wide range of weather conditions.

For more information, visit www.ivcco.com.

Fig. 6—Bermad’s FP/FS-400Y torrent valve.

Fire Protection Torrent Valve

he Bermad FP/FS-400Y torrent valve (Fig. 6) is a hydraulic, line-pressure-driven, elastomeric, rolling diaphragm globe valve approved for 25 bar. It is suited for vertical or horizontal installation and is available in pipe diameter sizes ranging from 1½ in. to 16 in. The valve is designed for flow control in deluge with or without pressure control, remote on/off, pressure reduction, and pressure relief. It can be used with any fluid in a fire protection system, including seawater and foam concentrate. The valve can be manufactured using different materials and coatings to suit a wide range of specifications and hazardous locations. Its detachable cover enables quick in-line inspection and servicing.

For more information, visit www.bermad.com.

Fig. 7—Ingersoll Rand’s MR150 Man Rider winch.

Cable Lifting Winch

Ingersoll Rand’s MR150 Man Rider winch (Fig. 7) combines emergency lowering, slack line detection, and redundant braking systems to ensure worker safety during lifting in oil and gas operations. The winch has steel guards to protect critical components and stainless steel polytetrafluoroethylene hoses and stainless steel drum guards for corrosion resistance.

For more information, visit www.ingersollrandproducts.com.